Ozgenc Makina Doorband 6500 I Máquina de Biselado de Bordes de Puertas

Especificaciones

| Fabricante | Ozgenc Makina |

| Modelo | Doorband 6500 |

| Condición | Nuevo |

| Número de Stock | 600874623 |

| Grosor de banda de borde | 0.4 - 1 mm |

| Grosor de banda para superficies texturizadas | 0.3 - 0.5 mm |

| Grosor del panel | 30 - 60 mm |

| Velocidad de trabajo | 9 m/min |

| Capacidad de pegamento | 3 L |

| Tiempo de calentamiento del pegamento | 20 min |

| Exhaustores de succión de polvo | Ø100 mm |

| Dimensiones | L 6500 x W 1625 x H 2260 mm |

| Disponibilidad | Inmediata |

Descripción

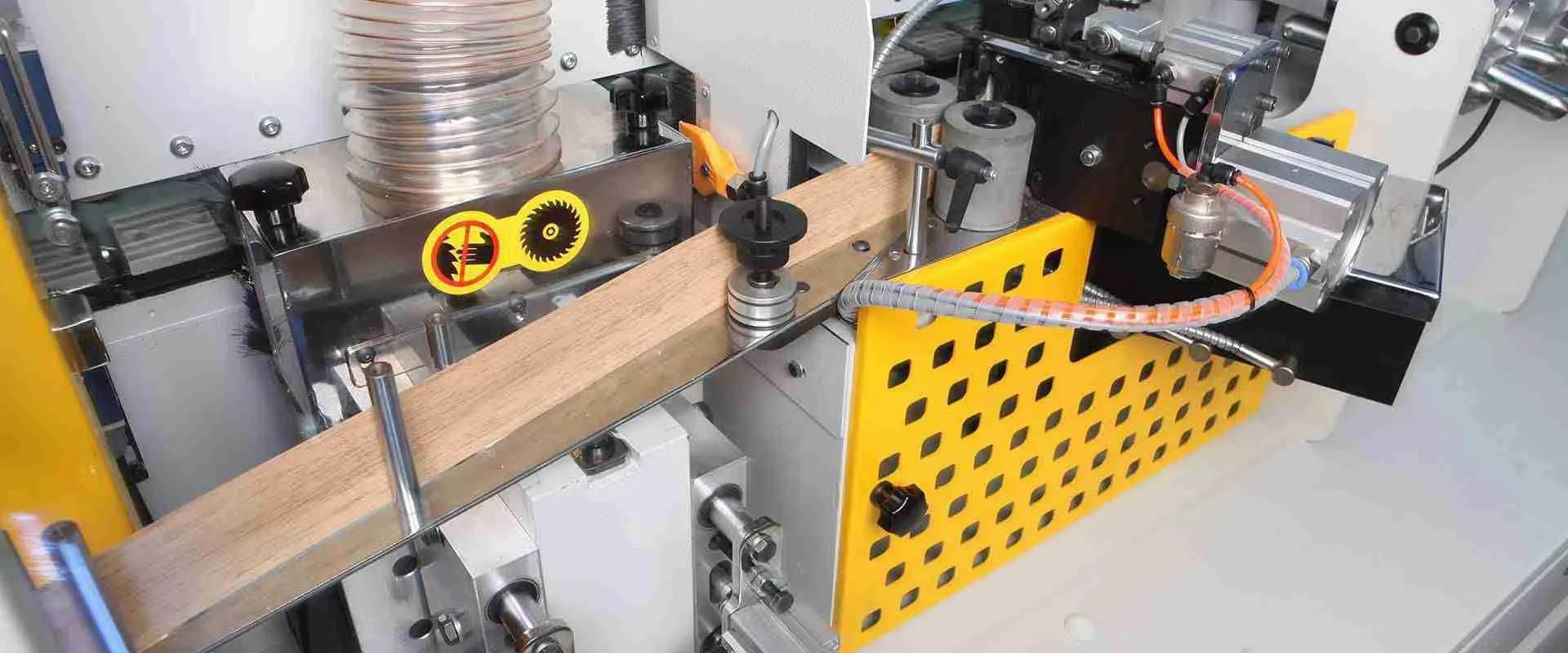

Discover this new Ozgenc Makina Doorband 6500 door edge banding machine, located in Turkey. Designed for efficient door manufacturing, this machine supports edge band thicknesses of 0.4 to 1 mm, ideal for fine detail. Its 9 m/min working speed allows for a quick, continuous workflow, while the supported panel thickness of 30 to 60 mm accommodates a variety of door sizes and materials.

Features:

- Performs the process of covering the vertical and straight edges of wood-based panel with a thickness up to 30 to 60 mm with PVC band with a thickness varying from 0.4 mm to 1 mm for aesthetics, strength, physical effects etc. reasons.

- It is designed to band the parts made from multilayer MDF, chipboard, etc. Parts made of any other materials than wood (plastic, marble, metallic materials, etc.) cannot be banded.

- It has pre-solvent, pre-milling (optional), form unit, end-front cutting, end-front rough cutting, bottom-top milling cutter (rough), bottom-top, milling cutter (finish), trim unit (optional), internal cleaning cutters for rabbeted doors, outlet solvent and polishing units.

- 3-L glue capacity (glue type: EVA / PUR granule).

- Band thickness of 0.4 - 1 mm for smooth surfaces, and of 0.3 - 0.5 mm for textured surfaces (0.3 mm CPL-0.4 mm PVC-0.5 mm interlining wood band).

Ozgenc Makina

Ozgenc Makina stands out as a top company in the window machinery industry, specializing in the production of machines for manufacturing Aluminum, Wood and uPVC windows and doors. Leveraging cutting-edge technologies, the company continuously enhances its equipment and designs to align with market demands. Their extensive range of window machines includes models tailored for seamless and reliable window manufacturing processes. With over 40 years of experience, Ozgenc Makina has expertise in developing equipment for uPVC windows & doors, such as cutting and welding machines, corner cleaning machines, and end milling machines, among others. Their window machines are esteemed worldwide for their reliability, functionality, user-friendliness, and ease of maintenance, meeting modern requirements and impressing manufacturers with a distinctive operational experience.

____

*Information may be inaccurate and subject to change without notice. This description could have been automatically translated, and details in this classified ad are indicative and subject to change. GLOMACH advises verifying specifications or else.

**Bidding is subject to specific circumstances and negotiation terms.