BRIO BR-6 AMS

Especificaciones

| Fabricante | BRIO |

| Modelo | BR-6 AMS |

| Condición | Nuevo |

| Número de Stock | GMT-BR6AMS |

| Número de stock | GMT-BR6AMS |

| Fabricado en | España |

| Bañeras de limpieza ultrasónica | 2 |

| Bañeras de enjuague | 2 |

| Bañeras de secado | 1 |

| Capacidad de las bañeras | 6 L |

| Capacidad total de fluidos | 24 L |

| Potencia total | 1150 W |

| Dimensiones | L 1390 x W 945 x H 1495 mm |

Descripción

Automatic Multistage Contact Lens Cleaning

Integral solutions for sanitizing sharps, prothesis, implants, etc.

At BRIO Ultrasonics we have extensive experience in solutions for manufacturers of orthopedic and traumatology prostheses, lenses, dental implants, instruments and for the medical and pharmaceutical industry in general. BRIO equipment is designed and manufactured with the high controls that must comply with all industry requirements, including cleanroom processes.

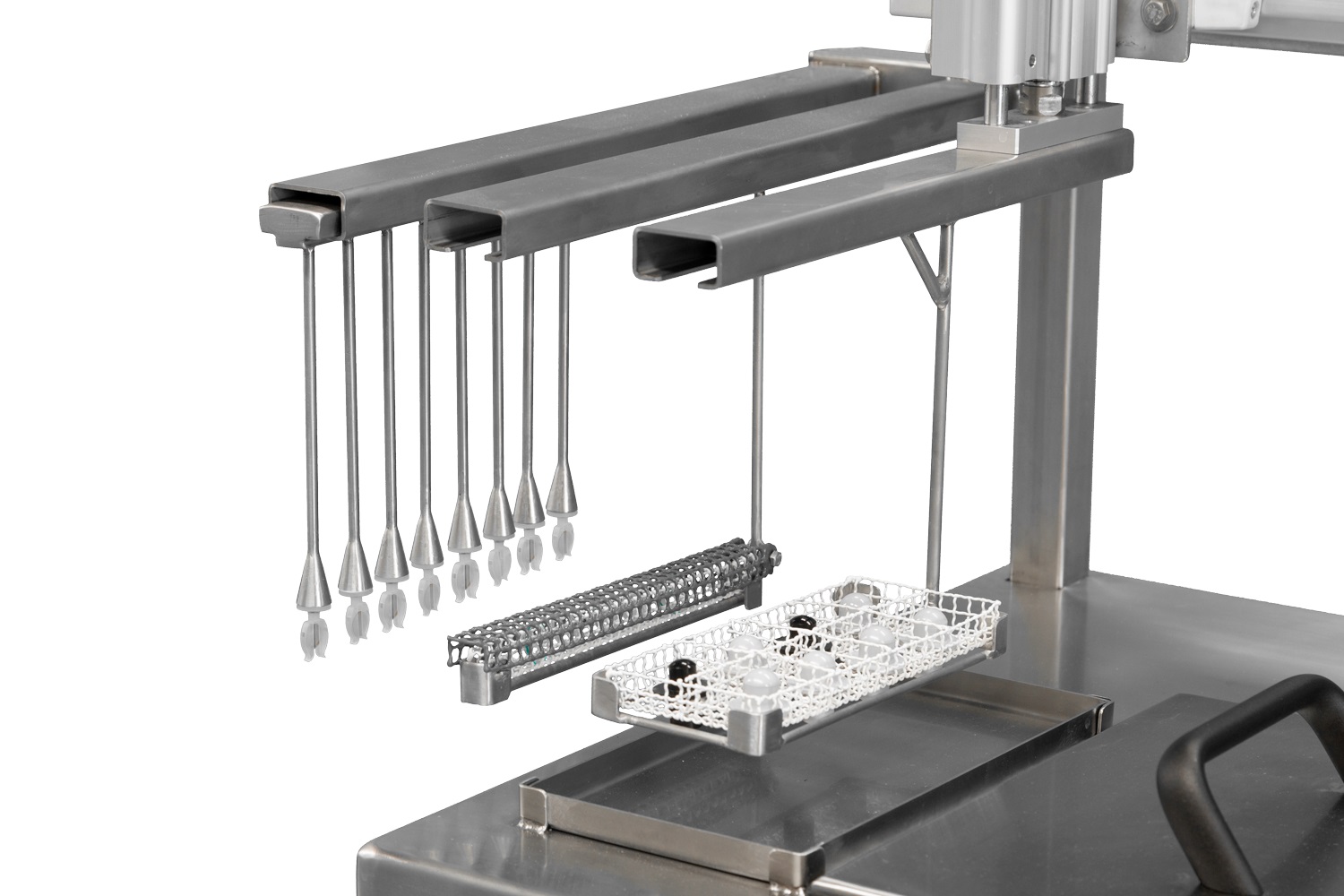

Within our line of multistage machines, we develop the BR-AMS line, automatic machines that we custom design for each sector and application. The definitive solution for cleaning and sanitizing instruments, components and parts. The BR-AMS machines have a robot arm that is responsible for transporting the tools through the different tanks, which means a great saving in staff time.

We install BRIO ultrasonic cleaning and sanitizing stages, rinsing, drying and pretreatment according to application. The ultrasonic immersion stages have our exclusive technology that allows total sanitation with maximum speed, accessing all the difficult points of the geometry of the pieces, without altering their shape and without altering their materials.

BR-AMS machines can be customized according to the needs of each client, varying the capacity of the tanks, number and type of stages, etc. We also design custom-made piece holders according to the type of piece to be sanitized

The operation and control is carried out from the touch panel in a simple and intuitive way, being able to program cycles and functions. Once the cycles have been programmed, it is only necessary to press a button for the machine to carry out the entire process. We also develop specific programs according to application.

More info:

Fully automated system with robot arm and PLC

Use and programming by touch screen

Multiple wash programs can be preset

For the removal of lens manufacturing material, cleaning of medical instruments, etc.