Vitap Point K2 2.0 I Centro de mecanizado CNC I 2021

Especificaciones

| Fabricante | Vitap |

| Modelo | Point K2 2.0 |

| Año | 2021 |

| Condición | Usado |

| Hecho en | Italia |

| Ancho de la pieza de trabajo | 180 - 1250 mm |

| Tamaño máximo del panel | X ∞, Y 1250, Z 50 mm |

| Tamaño mínimo del panel | X 270, Y 150 (70 opt.), Z 3 mm |

| Unidad de hoja de sierra | ø 100 mm |

| Cabezal de enrutador | 5 kW ISO 30 - 12000/24000 rpm |

| Espesor del panel | 50 mm |

| Peso del panel | 80 kg |

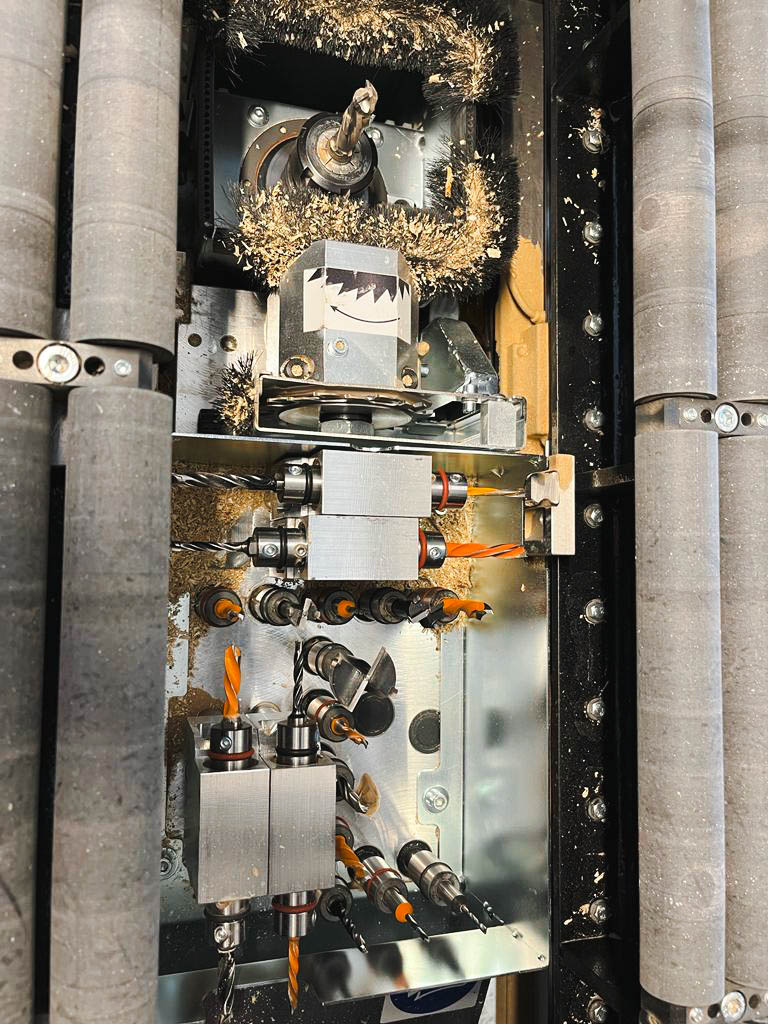

| Cabezal de taladro | 12 husillos verticales, 4 husillos horizontales en X, 4 husillos horizontales en Y |

| Número de ejes controlados | 3 |

| Velocidad de alimentación del panel | 25 m/min |

| Velocidad de rotación de los husillos | 3600 rpm |

| Velocidad de rotación de la hoja de sierra | 7000 rpm |

| Presión de aire | 7 bar |

| Profundidad de perforación horizontal y vertical | 50 mm |

| Potencia total | 7 kW |

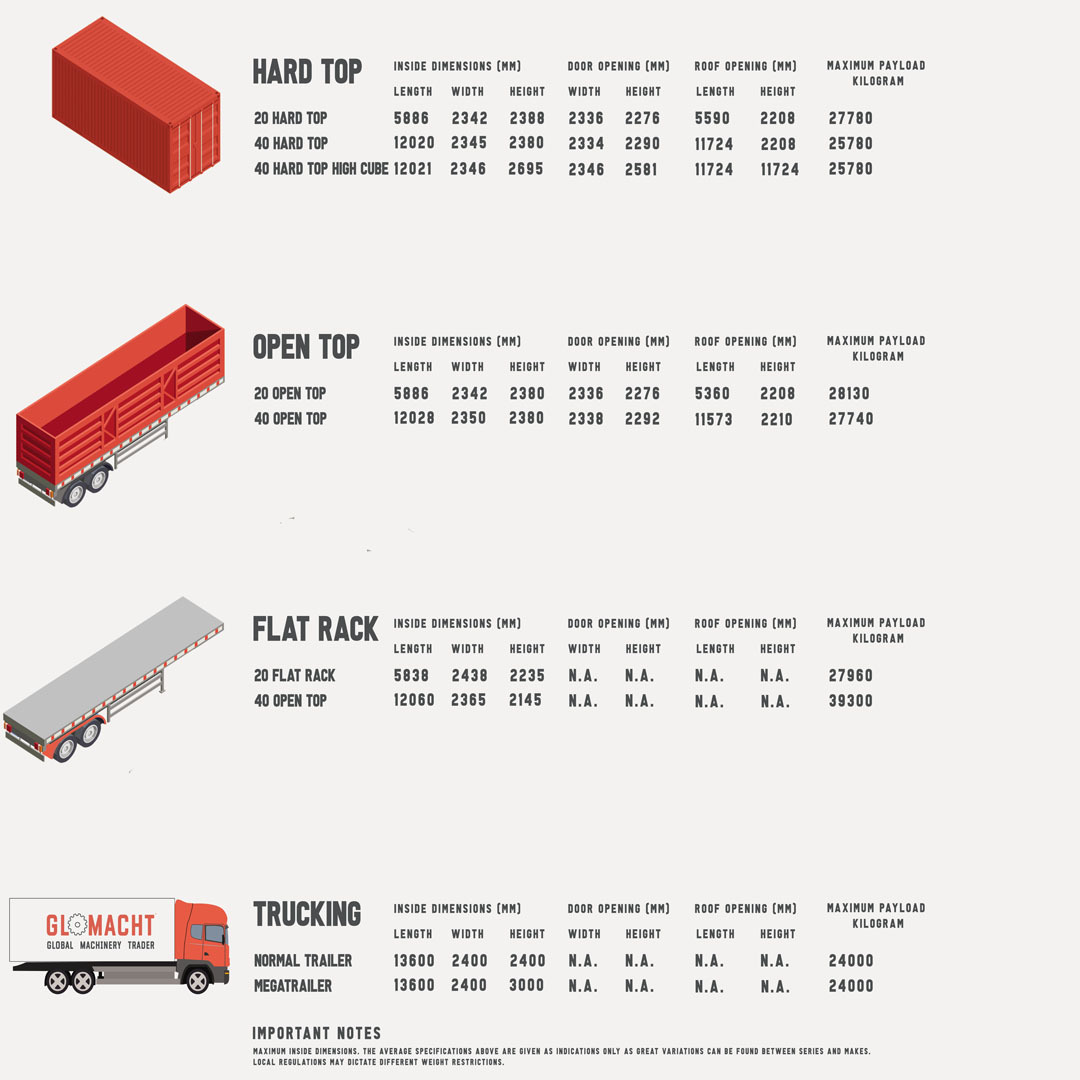

| Dimensiones | L 2900 x A 1650 x A 1890 mm |

| Peso | 950 kg |

| Disponibilidad | Inmediatamente |

Descripción

Explore this used Vitap Point K2 2.0 CNC machining center from 2021, located in Slovakia. This versatile machine boasts a workpiece width range of 180 - 1250 mm, catering to a variety of woodworking projects. With a robust 3600 rpm spindle speed rotation, the Vitap Point K2 2.0 ensures efficient and accurate machining. The total power of 7 kW empowers you to handle diverse tasks with ease. Invest in this reliable woodworking machinery to elevate your capabilities and achieve outstanding results in your projects.

Features:

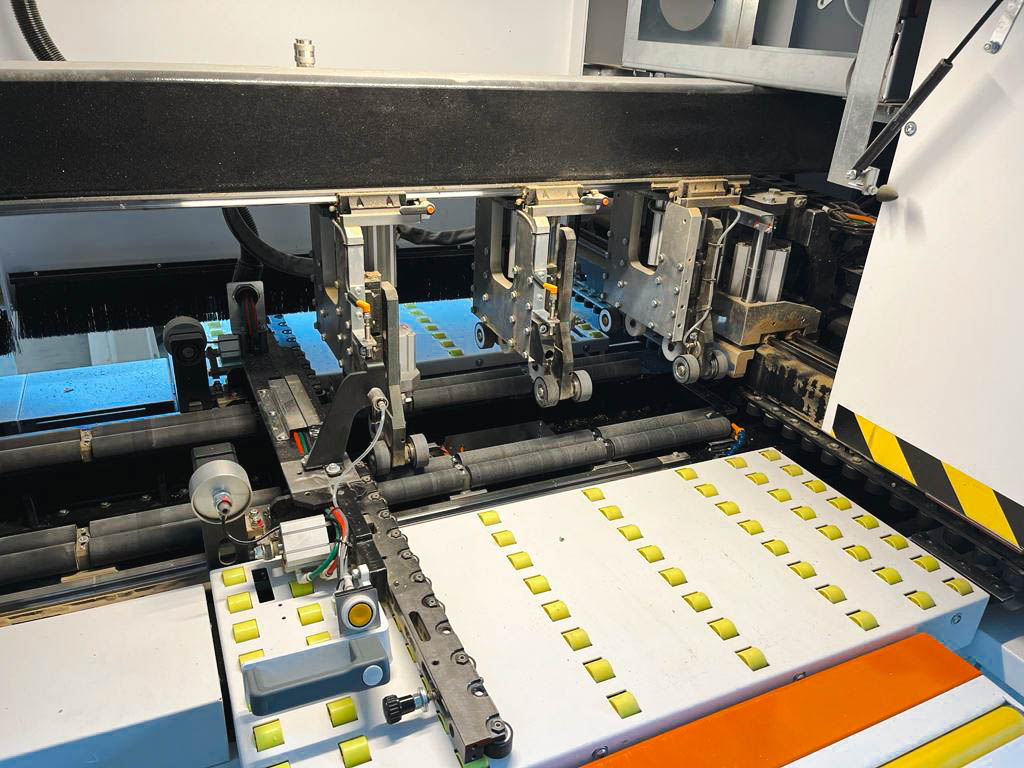

- DDT (Double Dynamic Transport).

- Allows you to make holes and mill without changing the collet.

- Bar Nesting system.

- CAD CAM software.

- It can also mill UKW profiles, profiled doors, various grooves, etc.

Included with the Machine:

- 4-place linear tool magazine.

- 2x roller table.

- 2x caliper for narrow parts.

- Manual.

- Office version of software on USB.

DDT (Double Dynamic Transport): System with two grippers with improved brushless motors for movement of the part in the X axis (smooth); can also work with one gripper for small parts. Allows you to make holes and mill without changing the collet. Sufficient stability of the part during milling has been achieved.

Bar Nesting system: Patented Vitap software for achieving all the advantages of nesting and no limits for horizontal drilling, 4-sided formatting.

____

*Information may be inaccurate and subject to change without notice. This description could have been automatically translated, and details in this classified ad are indicative and subject to change. GLOMACHT advises verifying specifications or else.

**Bidding is subject to specific circumstances and negotiation terms.