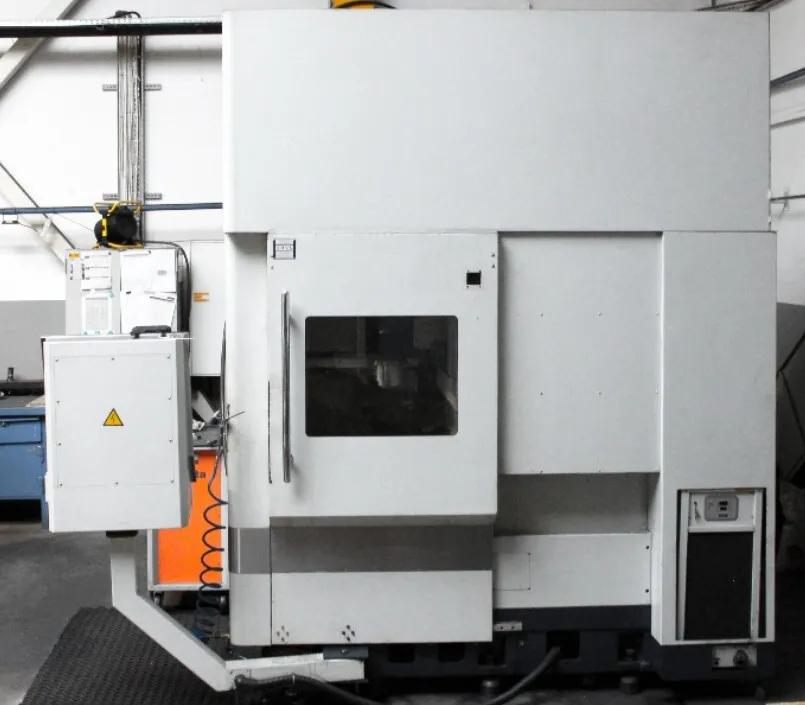

Centro de Mecanizado Vertical Spinner U5-620 I

Especificaciones

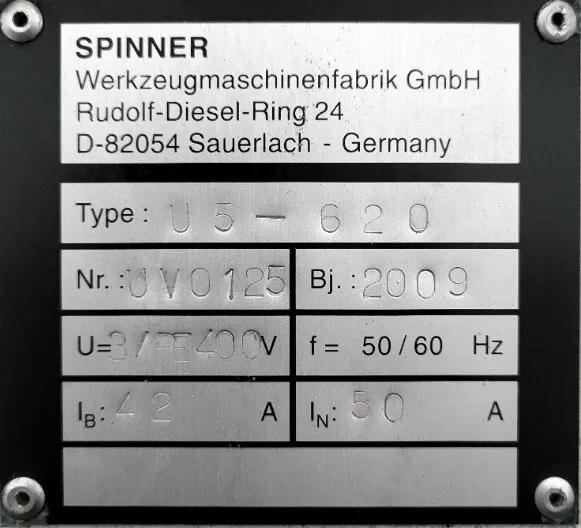

| Fabricante | Spinner |

| Modelo | U5-620 |

| Año | 2009 |

| Condición | Usado |

| Número de Stock | 6149487 |

| Hecho en | Alemania |

| Unidad de control | Siemens Sinumerik 840 D-SL |

| Recorrido del eje X | 620 mm |

| Recorrido del eje Y | 520 mm |

| Recorrido del eje Z | 460 mm |

| Recorrido del eje B | +60/-140º |

| Recorrido del eje C | 360º |

| Longitud de la mesa | 650 mm |

| Ancho de la mesa | 545 mm |

| Carga de la mesa | 500 kg |

| Cono del husillo | SK 40 |

| Velocidad del husillo | 9000 rpm |

| Potencia del motor | 22 kW |

| Revistero | 32 posiciones |

| Disponibilidad | Inmediata |

Descripción

We hereby offer this used Spinner U5-620 vertical machining center from 2009, located in Poland. Crafted to cater to the rigorous demands of the industrial sector, the Spinner U5-620 is adeptly equipped with the Siemens Sinumerik 840 D-SL control unit. With a generous working area of 650 x 545 mm, the Spinner U5-620 provides ample space for a variety of machining operations. A key feature of this vertical machining center is its high-performance capabilities, demonstrated through a spindle speed of 9000 rpm coupled with a robust motor power of 22 kW.

Features:

- 5 axes.

- 2-axis tilting table.

Spinner is a German machine tool manufacturer known for producing a variety of high-precision machining centers and turning machines. The company specializes in the development and production of CNC (Computer Numerical Control) machines designed for precision machining applications. Spinner's product range includes vertical machining centers (VMCs), horizontal machining centers (HMCs), and turning centers (lathes). These machines are used in a wide range of industries, including aerospace, automotive, medical, and general manufacturing. Spinner machines are recognized for their advanced technology, reliability, and versatility, making them suitable for various machining tasks such as milling, drilling, and turning. The brand is committed to providing cutting-edge solutions that meet the demanding requirements of modern machining processes.

____

*Information may be inaccurate and subject to change without notice. This description could have been automatically translated, and details in this classified ad are indicative and subject to change. GLOMACH advises verifying specifications or else.

**Bidding is subject to specific circumstances and negotiation terms.