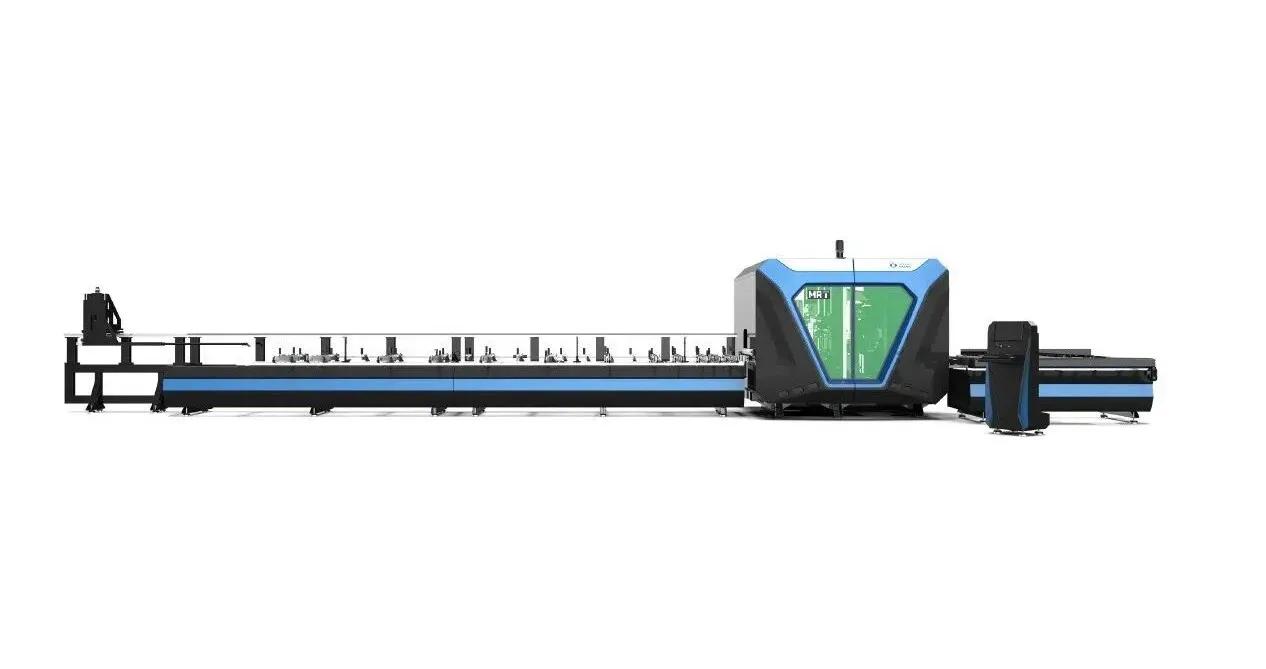

Centro de mecanizado de perfiles de aluminio Ozgenc Makina MRT 1967 I

Especificaciones

| Fabricante | Ozgenc Makina |

| Modelo | MRT 1967 |

| Condición | Nuevo |

| Número de Stock | 600874628 |

| Hecho en | Turquía |

| Diámetro de la sierra superior | Ø650 mm |

| Diámetro de la sierra horizontal trasera | Ø500 / 550 mm |

| Longitud de perfil mecanizable | 600 - 7000 mm |

| Ancho de perfil mecanizable | 30 - 200 mm |

| Altura de perfil mecanizable | 30 - 230 mm |

| Unidades de fresado | 16 de 3 kW cada una |

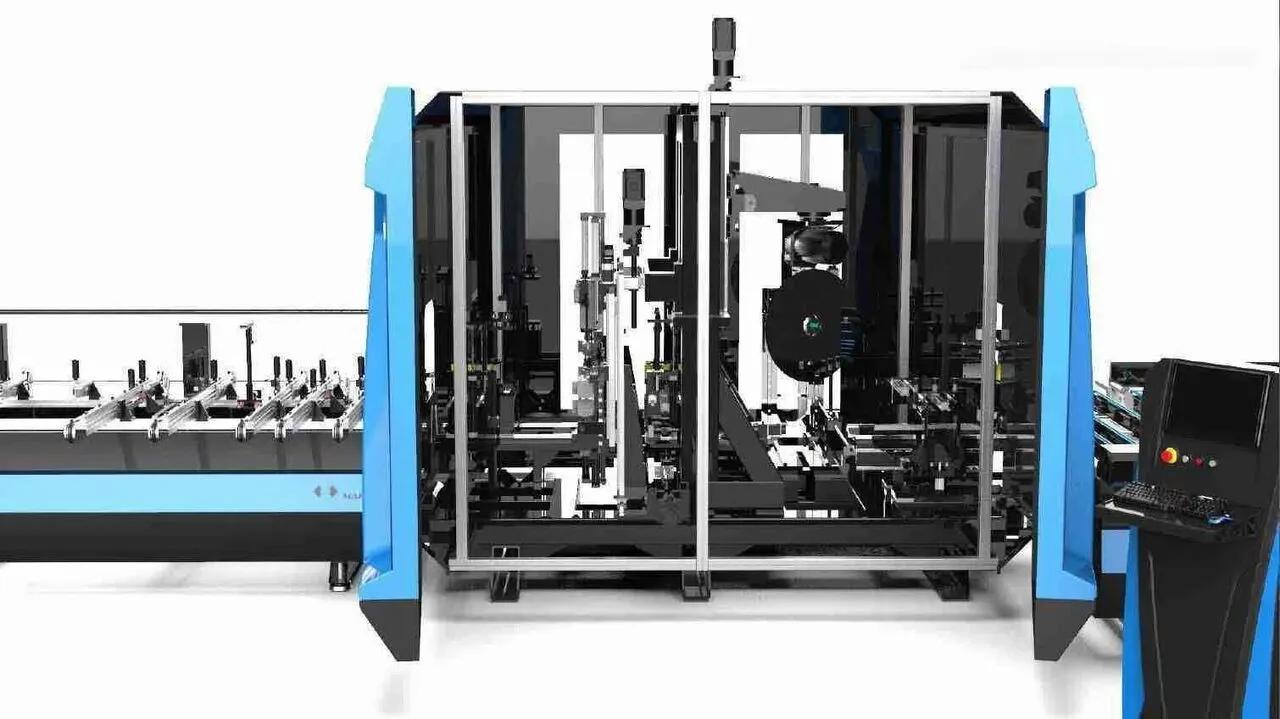

| Sierras superior y horizontal | con movimiento de rotación de 180° en 3 ejes |

| Potencia total | 32 kW |

| Capacidad de la mesa de alimentación | 6 perfiles |

| Dimensiones | L 24100 x W 5650 x H 2900 mm |

| Disponibilidad | Inmediatamente |

Descripción

Explore this new Ozgenc Makina MRT 1967 aluminum profile machining center, located in Turkey. It boasts a powerful 650 mm saw diameter, a machinable profile length of up to 7000 mm, and a total power capacity of 32 kW, ensuring efficient and precise cutting for various aluminum profiles. Perfectly suited for manufacturers seeking reliable, advanced machinery for large-scale aluminum processing.

Features:

- Compatible with all joinery and optimization programs.

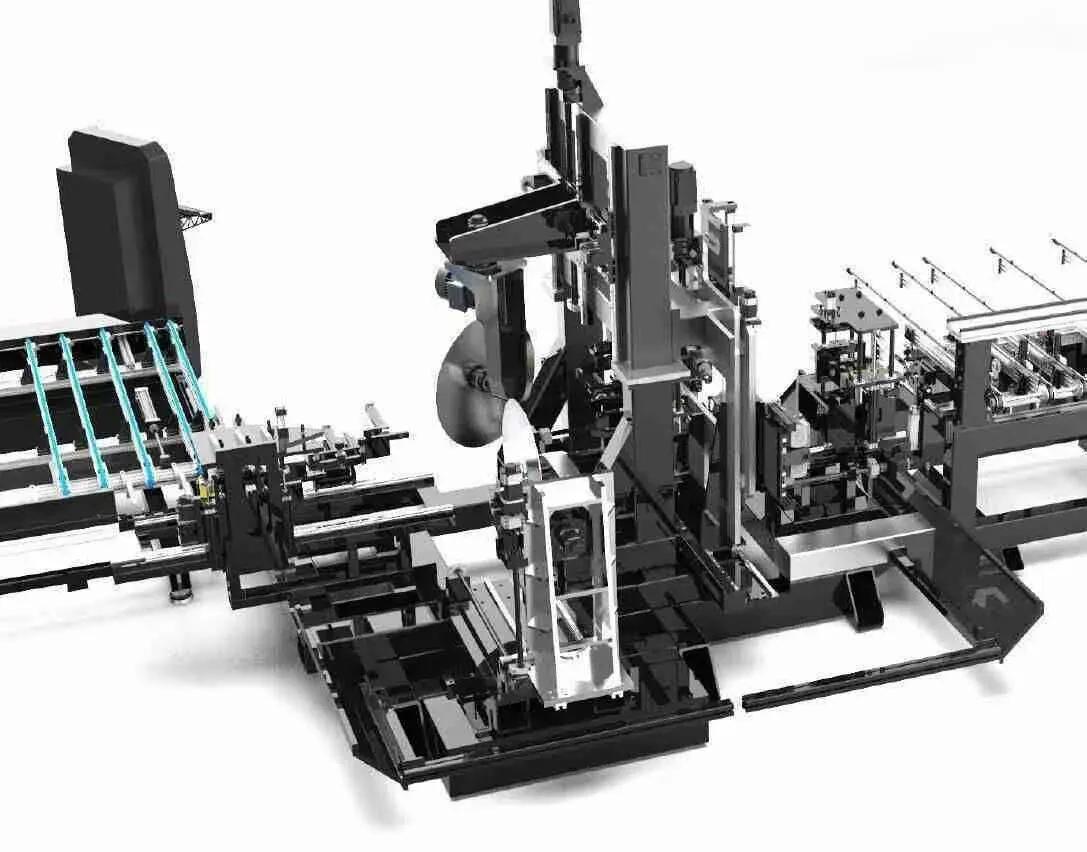

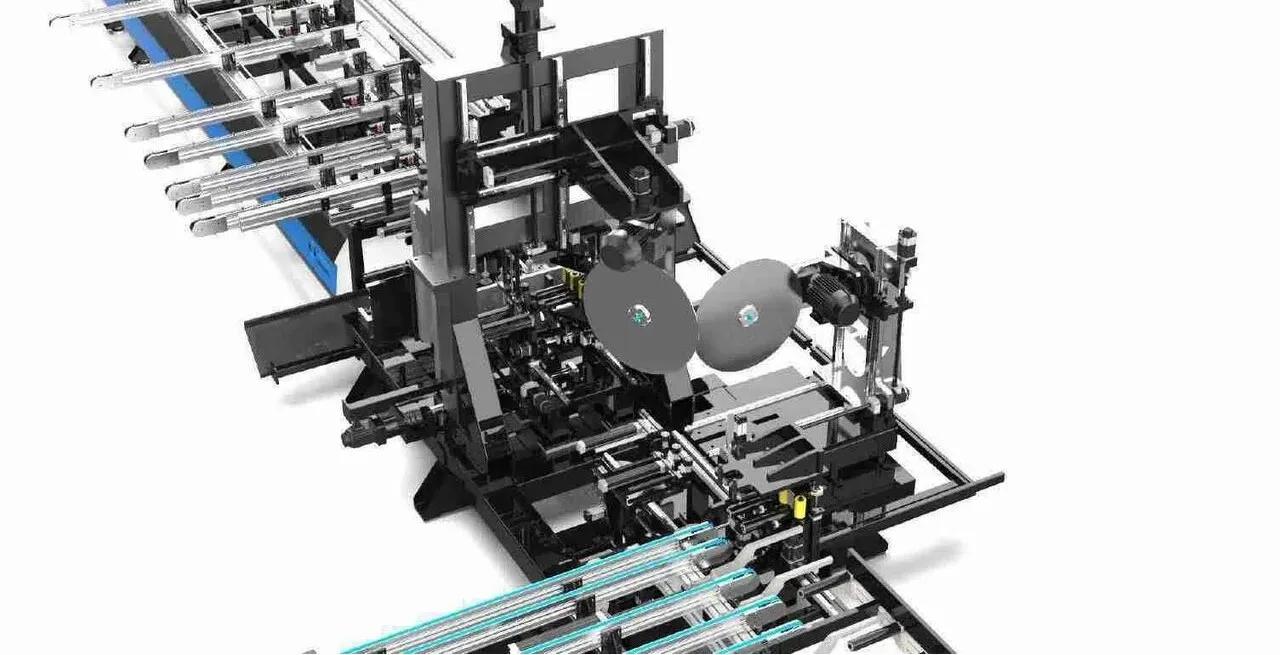

- Milling unit that enables processing on four surfaces of the profile.

- Profile vertical alignment system.

- Movable clamping units that can easily drive heavy profiles and increase processing precision.

- Special clamping units that completely surround the profile and prevent its free movement inside the machine.

- Capability to cut short profiles with movable output unit.

- Windows OS based control system with 21.5” screen.

- Automatic profile length detection feature that allows gripper to catch profile without wasting time.

- Capability of capturing all kinds of profiles at any desired angle with 3 axes and 360° rotating gripper arm.

- Ability to perform all kinds of facade notching operations on aluminum profiles.

- Minimised vibration during machining and more precise and clean machining with milling units fixed to the body with double rails.

- Stainless machine surfaces that prevent the profiles from being scratched.

- Trouble shooting and service opportunity with remote connection.

- Unlimited profile memory capacity.

- Servo motor control on all axes.

- Ability to send processing files generated by window and door design software to the machine via USB \ wireless and wired network.

- Label printing for every workpiece (including useful waste).

- Industry 4.0 compatible (processing speed, cutting reports etc.).

- Designing labels and barcodes as desired.

- Automatic lubrication system.

- Automatic cooling system.

Ozgenc Makina

Ozgenc Makina stands out as a top company in the window machinery industry, specializing in the production of machines for manufacturing Aluminum, Wood and uPVC windows and doors. Leveraging cutting-edge technologies, the company continuously enhances its equipment and designs to align with market demands. Their extensive range of window machines includes models tailored for seamless and reliable window manufacturing processes. With over 40 years of experience, Ozgenc Makina has expertise in developing equipment for uPVC windows & doors, such as cutting and welding machines, corner cleaning machines, and end milling machines, among others. Their window machines are esteemed worldwide for their reliability, functionality, user-friendliness, and ease of maintenance, meeting modern requirements and impressing manufacturers with a distinctive operational experience.

____

*Information may be inaccurate and subject to change without notice. This description could have been automatically translated, and details in this classified ad are indicative and subject to change. GLOMACH advises verifying specifications or else.

**Bidding is subject to specific circumstances and negotiation terms.